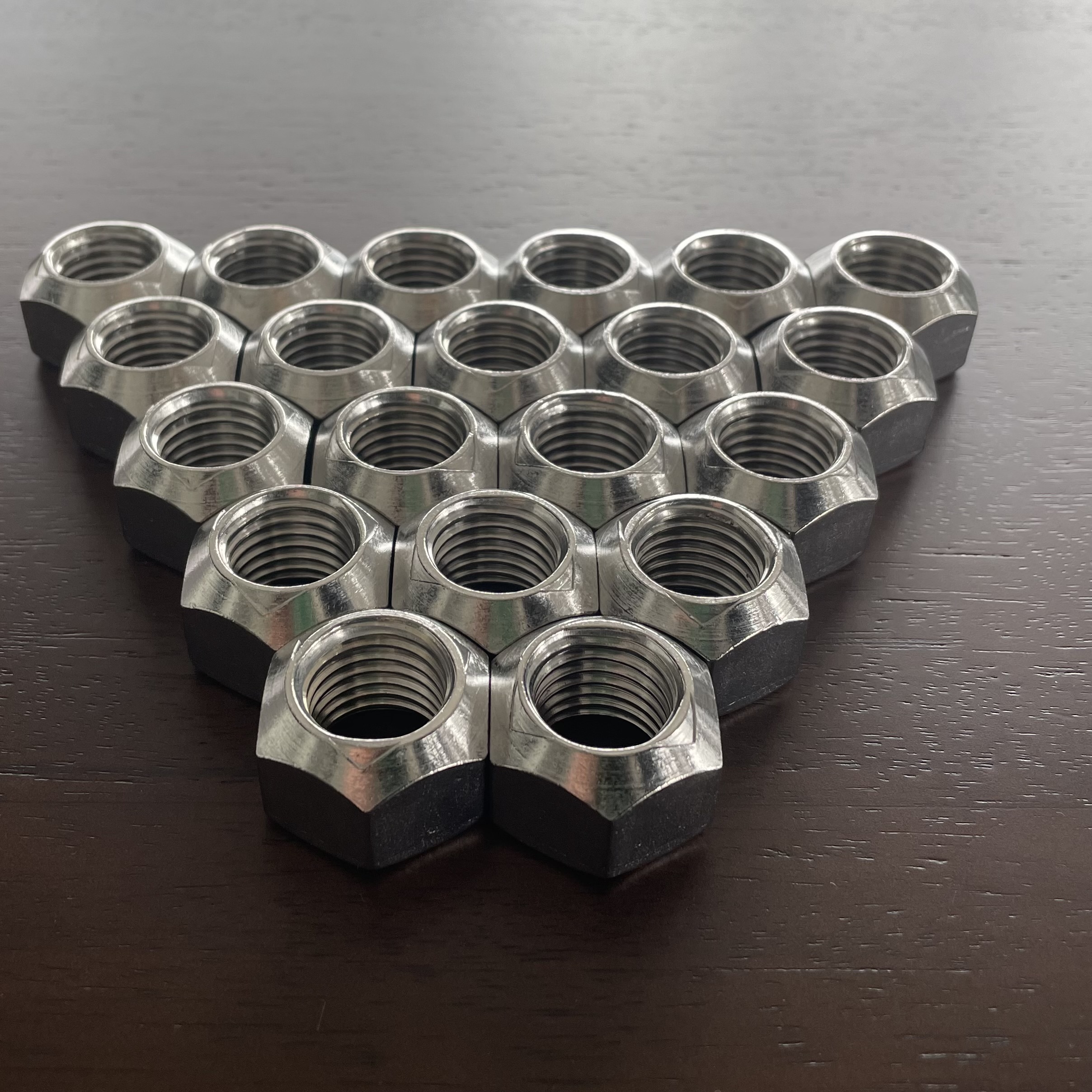

Introduction to All Metal Prevailing Hex Lock Nuts

Highlighting the importance of these lock nuts in preventing loosening under vibration and dynamic loads, exploring their design principles and how they differ from standard nuts.

Key Advantages

Discussing the durability, resistance to high temperatures, and reuse potential of all metal prevailing hex lock nuts, making them suitable for critical applications where reliability is paramount.

Applications Across Industries

Detailing the use of these nuts in automotive, aerospace, construction, and machinery, emphasizing their role in safety and reliability.

Installation and Removal Best Practices

Providing insights into the correct installation techniques and tools required for these lock nuts, ensuring maximum effectiveness and longevity.

Material and Coating Options

Exploring the different materials and coatings available, including stainless steel and zinc plating, to suit various environmental conditions and applications.

Challenges and Solutions

Addressing common issues encountered with these nuts, such as galling and torque consistency, and offering solutions to mitigate these problems.

Recent Innovations and Future Outlook

Looking at the latest advancements in design and materials, and predicting how these might influence the development of even more effective locking nuts.

FAQs

- What distinguishes all metal prevailing hex lock nuts from standard nuts?

- How effective are all metal prevailing hex lock nuts in preventing loosening under vibration?

- Can these nuts be used in outdoor applications?

- What sizes and materials are available for all metal prevailing hex lock nuts?

- How does the cost of all metal prevailing hex lock nuts compare to other locking mechanisms?

Conclusion

Emphasizing the critical role of all metal prevailing hex lock nuts in maintaining joint integrity across a wide range of applications, underscoring their importance in modern engineering. For more info, pls visit:Bolts Nuts and Washers Archives – Jiaxing Linkworld Fastener